Why / How steel is more elastic than rubber?

The greater the resistance to change, the greater is the elasticity of the material and the faster it comes back to its original shape or configuration when the deforming force is removed. If this definition is followed then definitely steel will win the race of elasticity.

A rubber band is not really very ‘elastic’. It is merely more stretchable. It cannot retain this property of regaining its original shape over the same range of force that a steel wire can. It merely stretches more than the steel wire. It is therefore not more elastic. It is merely more deformable.

Let’s consider an example:

The same pull exerted on a rubber band will stretch it more than it stretches a steel wire, where the stretching will be practically imperceptible.

But the steel wire will remain stretchable for a much higher force.

A rubber band will stretch easily for a small force that you apply with your fingers. But if you pull more and more, it simply snaps.

But the steel wire will be so strong that you will not be able to break it by pulling it with your hands.

The rubber band may stretch by about an inch before it snaps.

The steel wire will stretch only by a small fraction of a millimeter for the force you apply with your fingers.

If you suspend a heavy weight (say 10 kg) using this wire, it will survive. It will stretch by perhaps a fraction of a millimeter. When you remove the 10 kg weight, the steel wire will regain its original length.

If you then suspend a weight of 20 kg, the wire will still sustain it, and it will stretch twice as much. If you remove the 20 kg load, the wire will still be back to normal.

You can continue this, and depending on the size (diameter) of the steel wire, the upper limit may be several hundred pounds.

But if you repeat the experiment with a rubber band of the same size (diameter) as the wire, you will find that the initial 1 pound load will stretch it by several inches (not a fraction of a millimeter), and any further increase will deform it permanently or even break it. When the load is removed, the rubber band will not regain its original shape. So it is a lot less elastic than steel.

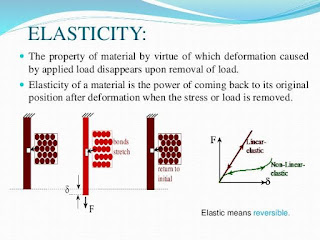

The key is in understanding the technical definition of ‘elastic’.

It should not be confused with the amount of stretching.

Once you understand this and interpret it as the range of force where it remains stretchable (however small the amount of stretching) , or the magnitude of the force that you need to apply to cause a predefined amount of stretching, you will understand why steel is always more elastic than rubber.

The confusion in the minds of non-engineers is due to the difference in meaning of elasticity when used by engineers and when used by non-technical people.

Here you can buy Stretch Slipcovers Sectional Elastic Stretch Sofa Cover for Living Room Couch

ReplyDelete